Bearing, also known as bantalan in Indonesian, is one of the essential components in machines that plays a significant role in enhancing efficiency and performance across various industrial sectors. In this article, we will delve into the function of bearings and how they serve as a key element in maintaining optimal machine performance in the era of modern industry.

Introduction to Bearings

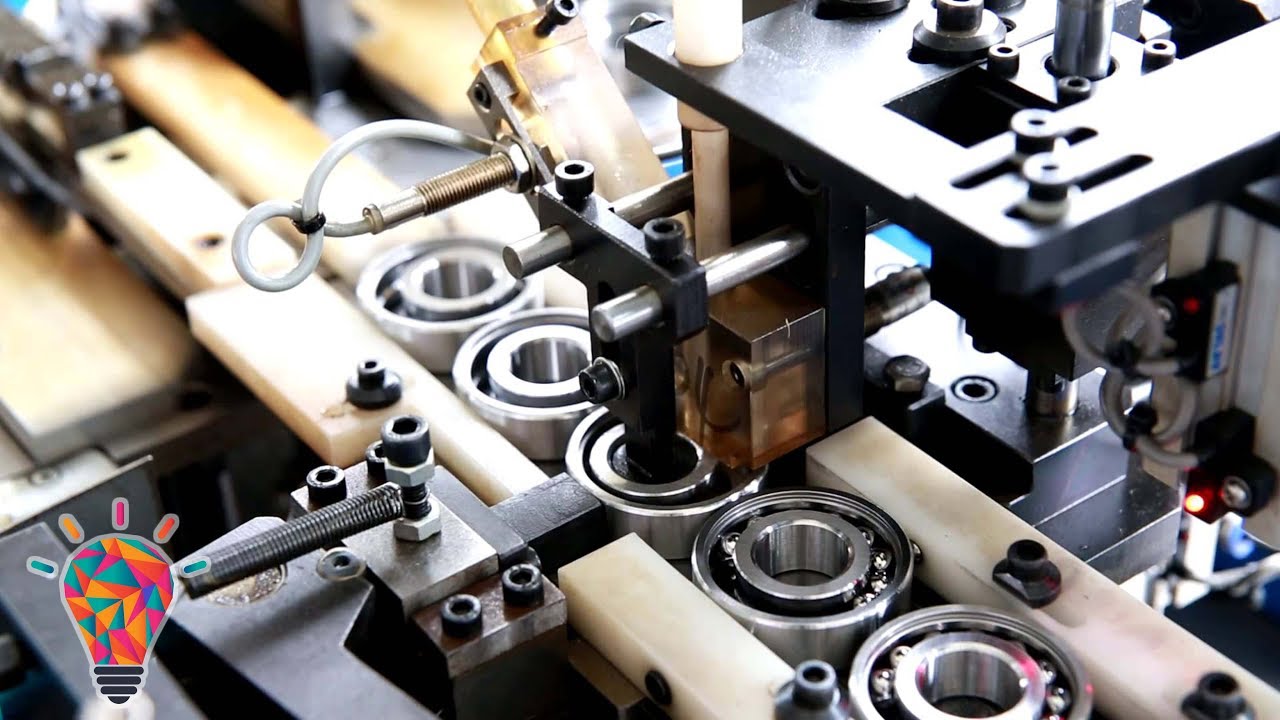

Bearing, or bantalan, is a mechanical element that facilitates relative movement between two machine components. In general, bearings function to reduce friction between contacting surfaces, allowing for smoother and more efficient movement. Therefore, the role of bearings is crucial in reducing energy losses due to excessive friction and in extending the lifespan of machine components.

Main Functions of Bearings

1. Reducing Friction and Wear

The primary function of bearings is to reduce friction between moving surfaces, such as shafts and outer rings. Excessive friction can lead to wear on metal surfaces, shorten the machine’s lifespan, and even cause permanent damage to components. With bearings in place, friction can be minimized, thus reducing wear and losses due to friction.

2. Supporting Heavy Loads

Bearings are designed to withstand heavy loads in various directions. Their ability to support these loads enables machines to operate stably and efficiently, even under heavy load conditions. Without bearings, mechanical movement would become difficult, unstable, and at risk of causing machine failures.

3. Facilitating Linear and Rotational Motion

Bearings come in different designs to suit various applications. Some bearings facilitate linear motion, such as wheel bearings in vehicles, enabling forward and backward movement with minimal friction. On the other hand, rotary bearings, as used in electric motors, allow smooth and efficient rotation of shafts.

4. Stabilizing Temperature

Bearings also function to absorb and reduce heat generated during machine operation. By reducing excessive heat accumulation, bearings help maintain a stable temperature in the machine and prevent damage caused by overheating.

Applications of Bearings in Industries

The crucial function of bearings makes them indispensable components across various industries. Some applications of bearings include:

- Automotive Industry: Bearings are used in wheels, transmissions, and other engine parts to support vehicle movement and reduce friction.

- Manufacturing Industry: Production machines utilize bearings to reduce loads and enhance the accuracy of component movements.

- Renewable Energy: Wind turbines and hydroelectric turbines use bearings to optimize efficiency and reduce friction.

- Aviation: The aviation industry employs bearings in aircraft engines to reduce friction and stabilize critical component movements.

The function of bearings as a critical element in modern industrial machines is undeniable. Their presence helps enhance efficiency, reduce damage, and extend the lifespan of machines. Various industrial sectors heavily rely on the optimal performance of bearings to achieve high levels of productivity and reliability.

As professionals in the field of engineering or industry, understanding the function of bearings and their importance in maintaining machine performance is essential. With a deep understanding of bearings, professionals can take appropriate preventive measures and maintenance steps, thereby creating reliable and efficient systems in the rapidly evolving world of industry.

Since 1973, PT Garuda Bearindo Makmur has been the Supplier and Leading Distributor of brands like SKF, FAG,Koyo, NTN, NSK, Fyh,IKO,INA,JNS,SAMICK in Indonesia. We sell our bearings to factories, bearing shops in Glodok, and throughout Indonesia.